FROGSKIN™: The perfect tool to add texture to your products

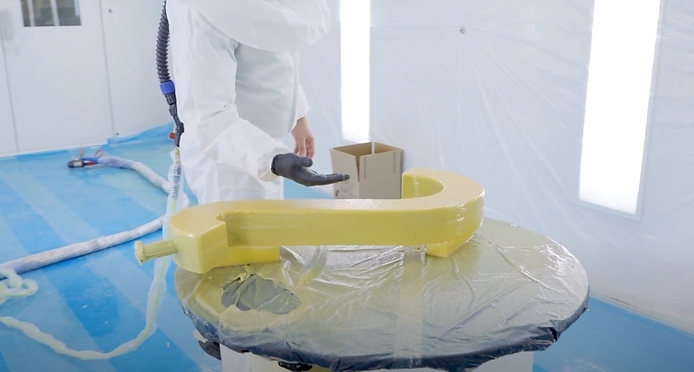

FROGSkin™ is the perfect coating solution for all your textural needs! Our product is the ultimate solution for adding textured finishes to your sculptural, themed, or architectural pieces. At Streamline Automation, we have incorporated FROGSkin™ with ease of use in mind, and our product is ideal to work within an industrial environment. Our product is an electric spray system for applying a protective coating to your masterpieces to provide long-lasting, smooth, or textured finishes. The FROGSkin™ is a plural component proportioner system that oversees the pressure and temperature of the materials. It also uses powerful heating like a hybrid heater that provides up to 10,200 watts of heat to pre-heat material instantly. The FROGSkin™ protects against blockage and breakage, and its convenient Pressure Imbalance Detection™ system detects pressure imbalances and automatically shuts the system down before you potentially ruin your spray job. The FROGSkin™ system maintains consistent pressure between materials, and also warms the material to a temperature that will promote atomization for effective spraying.

FROGCOAT™: The right coating materials to extend product durability

FROGCoat™ refers to materials that are sprayed onto the surface of your product. We have a complete line of coatings and related materials to suit your different coating needs. We use an impact and UV- resistant material much like a truck bed liner- it’s a hard and rubbery material which provides you with a long-lasting finish. FROGCoat™ coatings will give you the durable end result you need for your architectural, sculptural, and themed product needs to withstand the elements, all the while providing a look that stands out in a crowd.

Polyurea is a commonly used coating material and comes in a variety of chemical mixtures. This allows a plethora of options that cater to your specific needs and is also an environmentally-friendly material with no solvents or VOC emissions. When isocyanate reacts with a multifunctional amine, polyurea is formed. This reaction may happen in a matter of seconds depending on the mixture and can be applied in thickness in a single session. After this process, the cured coating is ready for paint. The coating is fast-setting, chemical resistant, and suitable for indoor and outdoor use. FROGCoat™ coatings can withstand harsh elements such as snow and rain, are waterproof, fire-rated, and UV stable. In addition, FROGCoat™ coatings will allow you to create durable and sophisticated molds that will consistently create beautiful end products.

Streamline Automation relies on professional chemical companies to supply us with materials, and our extensive experience with clients and many years of experience in this market have made us experts to suggest the best material for your various needs. The FROGCoat™ and FROGSkin™ work cohesively to yield a long-lasting surface coating for all your finished pieces. Interested in finding out more about which coating materials work for your project? Call us today!