Home » Maintenance

FROG3D® MACHINE MAINTENANCE PACKAGES

Keep Your Equipment Performing At Its Best!

At Streamline Automation, we’re dedicated to helping you get the most out of your system — today and for years to come. We offer a variety of service and maintenance options designed to keep your machines operating smoothly, prevent unexpected downtime, and ensure your production runs at peak performance.

We see every visit as part of a long-term partnership with you. Our technicians take the time to understand your setup, address your concerns, and keep your system performing at the top of its ability. Every maintenance visit is tailored to your specific System, but generally includes:

Mechanical Inspection & Cleaning

- Inspect and clean drive systems (rack and pinion gears, belts, etc.)

- Clean and lubricate linear motion systems (rails, bearings, and guideways)

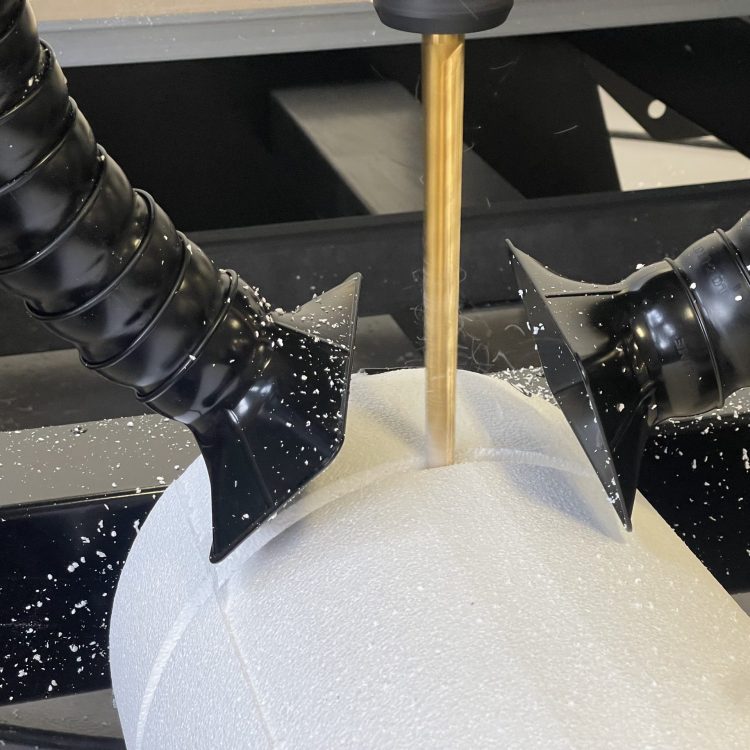

- Check cutting systems — including spindle bearings and hotwire connections — for wear or debris buildup

- Replace or resurface tabletops

System Calibration & Performance Testing

- Check for and adjust any backlash

- Perform distance and cut calibration tests to confirm precision tolerances

- Verify smooth and accurate machine movement across all axes

Electrical & Software Health Check

- Inspect electrical cabinet components and connections

- Test all safety interlock systems (E-Stops, faults, etc.)

- Clean up the system PC and update the operating system or software if required

Custom Requests

Every facility is unique. Our technicians can address specific issues to ensure your system continues to meet your production requirements.

Preventative Maintenance: Protecting Your Investment

We believe the best maintenance is preventative maintenance. By identifying wear and potential issues early, we help you avoid downtime, extend component life, and maintain consistent quality output.

Our Preventative Focus Includes:

- Cleaning dust and debris from cutting and motion systems

- Checking and lubricating bearings, belts, and gears

- Inspecting connections for corrosion or wear

- Updating software and firmware for peak reliability

- Verifying calibration accuracy for consistent results

Preventative care helps ensure that your system remains reliable, accurate, and efficient — reducing costly repairs and keeping you focused on production.

Due to the personalized nature of the FROG3D® approach, prices vary. We are happy to supply an estimate for a full package, addressing all needs beyond just maintenance. We also offer in-person training on software, basic machine operation, and machining strategies, and a combined estimate is available upon request!

To learn more about FROG3D® maintenance packages, Contact Us Today!

Check Out Our Blog For More FROG3D® Maintenance Tips!

Starting The Year Right: Maintenance Tips For Your CNC Equipment

Table of Contents The advent of CNC machines has made manufacturing easier, faster, and more precise. CNC machinery and equipment are considered a critical piece