*Deduct the FULL PURCHASE PRICE of new or used FROG3D® equipment from your income,

up to $1,160,000!

*Offer available in the U.S. only

FROG3D® Software is Now Available on a Monthly or Annual Subscription Basis.

Test it out with a *31-Day Free Trial!

*Trial available for FROGShape™, FROGLathe™, and FROG4D™ only.

PROVIDING INTEGRATED SOLUTIONS FOR COMPLEX 3D PROJECTS

Equipment • Software • Training

Schedule a Discovery Session!

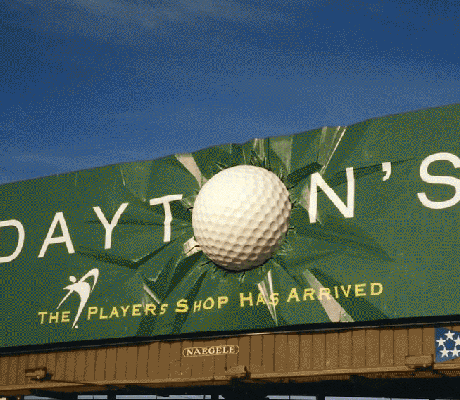

FROM VISION TO REALITY

Experience the revolutionary capabilities of automated 3D CNC carving.

Before

After

Industry Applications

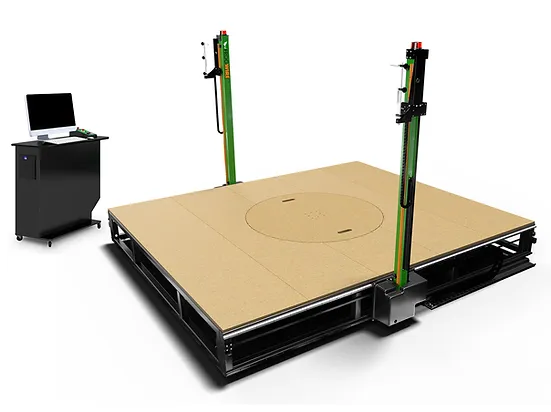

Equipment

FROG3D® brings advanced 3D fabrication capabilities to your production challenges. Creative, adaptive, exceptional, our turnkey 3D CNC fabrication system gives you the tools to work bigger, better, and faster. With cutting-edge technology, commercial-grade construction and industry leading training and support, FROG3D® bridges the gap between your creative process and production needs.

Check out these Deals on our FROG3D® Equipment!

Helping our customers succeed.

"As our business was growing, we were looking to extend our capabilities in 3D cutting & carving and decided to buy 2 machines from the FROG3D family. This investment allowed us to take the fabrication of 3D projects to new creative levels while increasing our production capabilities. We can’t wait to bring new ideas to life!"

Yves VervloetOwner Y-LINES

“In the past, we would hand sculpt the details of each creature we make with a manual process that could take up to a year. Using a FROGMill machine has cut that process down significantly. We now digitally 3D model the creatures before using our FROGMill machine to carve our creatures out of foam. The more time we save on each creature, the more we can do and expand our abilities.”

Billings Productions

“It's a rare case these days that you find a company with so many people so willing to focus on customer service and have the integrity to do it with patience, understanding, and genuine care about their customers' concerns and needs. FROG3D is a shining example of such choices. Not once did we feel pressured to make any decisions, or felt like we were being upsold to anything. The company as a whole, clearly values sincerity, understanding, and longevity of their customer's success and progression. Thank you for being innovators and inventors, it shows in your product, your work, and your people.”

Adam CatlettProduction Manager LFX Filmworks

“When we reached out to Streamline Automation, Ltd , they were able to build a custom hot wire machine that fit our needs perfectly. Every step of the way from our first ideas, to manufacturing, to installing, they have been right there with us to help us increase our production speed and accuracy. Great support, great machines, great people.”

Kevin R. WalshPurchasing Manager VANOCUR

"With the FROG3D® system, production has multiplied in efficiency and the product-range has boomed. The detail and quality of the designs are maintained or improved, and the precision of more complex builds is now significantly easier to accomplish"

Martin HögbergCEO ARCLIGHT FX

"The impact that the FROG3D equipment has had on our company is beyond anything we could have imagined. The powerful tools by FROG3D in the hands of our talented team of makers has allowed us to create truly impactful works of art for our clients. The FROG3D equipment has been one of the best investments our company has ever made, opening up many doors that were previously closed."

Niko SolomosSales & Marketing Manager DISPLAY GROUP

Previous

Next

RESOURCES

© Copyright 2023 Streamline Automation Ltd.2